John Deere 3046R Compact Tractor Cab & Loader

Get in the Seat with John Deere's October Sales Event!

**CASH SALE PRICE SHOWN** Financing is Available, Prices May Vary Depending on Rate and Term, Contact us for more info!

ORDERED OPTIONS:

1520 EHYDRO TRANSMISSION

1701 1550MM BUCKET 3R

2060 DELUXE CAB W/AIR RIDE

2660 RADIO (CAB ONLY)

3330 DUAL&SINGLE E-HYDR RE

3420 MID PTO

4061 LESS IMATCH QUICK HIT

5230 W&T, 43X16-20 4PR, R4

6230 W&T, 27X8.50-15 6PR

- Powerful and reliable Yanmar Diesel Engine

- AutoConnect™ deck compatible for deck attach/detach in seconds

- Cab or Open Station configuration available

- Standard hydrostatic transmission with Twin Touch™ pedals

|

Attractive styling provides improved visibility and serviceability

The bold styling of the tractor provides an attractive and functional appearance similar to that of the larger agricultural tractors. Benefits of this styling include:

The result gives the tractor a distinctive appearance and feel. NOTE: If tractor is equipped with optional field-installed vertical exhaust, exhaust pipe must be removed before opening and closing the hood of the tractor. | ||||||||||||||

|

Powerful, diesel engine delivers plenty of power under heavy loads

The Yanmar 3-cylinder, TNV series diesel engine features a high torque reserve that provides plenty of power under heavy loads.

*Engine hp (kW), gross SAE J1995: 45.3 (33.34) at 2600 rpm, PS The engine uses the latest technologies to optimize fuel economy, improve control and accuracy, and reduce environmental impact. The common rail system (CRS) optimizes fuel economy and reduces operating costs*. High-pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and a lower cost of operation. The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions. The engine comes with an after-treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed, or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC). After many hours of use, the exhaust filter may require an ash removal service. *NOTE: As compared to engines not using CRS technology. | ||||||||||||||

|

DPF cleaning The engine uses latest technologies to optimize fuel economy, improve control and accuracy, and reduces environmental impact. The common rail system (CRS) optimizes fuel economy and reduces operating costs*. High pressure injection atomizes fuel into finer particles which burn more completely. It results in improved fuel economy and lower cost of operation. The electronic control unit (ECU) provides optimum fuel control and accuracy. ECU monitors and controls the engine. It continuously monitors engine conditions and adjusts the fuel delivery accordingly to ensure optimum performance and emissions. The new engine comes with an after treatment system. The system operates automatically. The exhaust filter consists of a diesel particulate filter (DPF) which captures particulate matter (PM) contained in the exhaust gas. Using a natural cleaning process, most of the PM trapped in the exhaust filter is eliminated by the heat of the exhaust stream generated by normal use. In situations of low temperature, engine speed or load factor, an active cleaning cycle is initiated. In this cleaning cycle, the exhaust gas temperature is raised by injecting additional fuel during the exhaust stroke of normal vehicle operation to the diesel oxidation catalyst (DOC). After many hours of use, the exhaust filter may require an ash removal service. NOTE: *As compared to engines not using CRS technology. DPF cleaningDepending on the load that the tractor is under, as well as ambient temperature, humidity, and engine speed, the DPF may build up with particulate matter, thus requiring cleaning. Filter cleaning is determined by one of three conditions:

Once one of the three conditions has been met, filter cleaning will occur. There are three different types of filter cleaning processes:

Passive filter cleaning Passive filter cleaning occurs naturally when the engine is generating enough heat to oxidize particulate matter. This automatic process occurs continuously during normal operating conditions. No tractor icons or symbols appear on the display during passive filter cleaning.

NOTE: Passive filter cleaning requires no operator involvement, and there is no interruption to tractor operation.

If conditions (temperature, load, or speed) for passive filter cleaning cannot be achieved, then PM is removed using active filter cleaner. To achieve the required conditions, exhaust temperature management (ETM) manages the initiation and duration of active filter cleaning. ETM can adjust numerous engine parameters and/or inject a small quantity of fuel into the exhaust stream for a short duration. The fuel turns to vapor and chemically reacts with the catalysts in the DOC to create heat to oxidize PM. It is important to note that at no time is the fuel in the DOC/DPF ignited, and there is no flame within the DOC/DPF. Like passive filter cleaning, active filter cleaning requires no operator involvement, and there is no interruption to tractor operation. Parked filter cleaning In some instances where passive and active filter cleaning have not fully cleaned the PM from the system, a parked filter cleaning may need to take place. Most likely, the only time a parked filter cleaning will need to occur is when automatic filter cleaning has been disabled for an extended period of time and multiple warnings to engage filter cleaning were ignored or if the tractor has been used during light load conditions. Additionally, when the automatic filter cleaning process has been deliberately interrupted multiple times, or if active filter cleaning has failed numerous times due to a failed component, a parked filter cleaning may be requested. In these rare instances the operator will have to park the tractor and start the filter cleaning process. The parked filter cleaning process needs to be activated based on usage and operation of the tractor. The process will take approximately 30 minutes. See operator’s manual for more details. This system constantly monitors the soot level of the tractor, making sure the tractor is always in peak performance condition. This ensures high performance at all times.

NOTE: Number of hours since last regeneration and soot level percentage viewable on LCD display.

| ||||||||||||||

|

Key features of the engine are:

| ||||||||||||||

|

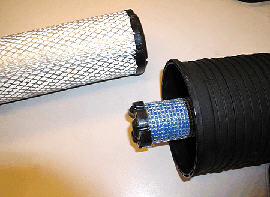

Dry-type air cleaner

Yanmar is a trademark of Yanmar Company Limited. | ||||||||||||||

Maximize productivity with an eHydro™ transmissionThe 3R Series Tractor is available with an exclusive three-range electronic hydrostatic (eHydro) transmission.

The electronic hydrostatic transmission is ideally suited for jobs where productivity is a must, such as loader or mower applications. Twin Touch™ foot controls allow selecting both direction of travel and speed with a touch of the toe. | ||||||||||||||

Key features of the eHydro transmission are:

Sauer-Danfoss eHydro transmission is used for reliable operation. Durability features include: 1) Large forged trunnion shaft with larger support bearings to reduce vibration and noise. 2) Center section made from durable cast aluminum, which is 10 percent stronger. 3) Transmission oil cooler cools transmission oil for longer transmission life.

| ||||||||||||||

|

Key John Deere advantage

John Deere's Twin Touch foot controls offer several key advantages over competitive hydrostatic transmission (HST) tractor models. Key advantages over competitive HST tractor models:

| ||||||||||||||

|

The eHydro convenience controls have been integrated into a single module. Combining features such as SpeedMatch™ LoadMatch™, MotionMatch™ eThrottle™ and automotive style cruise control pulls the maximum efficiency out of the eHydro transmission tractors. All of these features are standard on the 3R models, and deliver an easier and more comfortable user experience. | ||||||||||||||

|

eThrottle

| ||||||||||||||

|

Automotive-style cruise control

An automotive-style cruise control is standard equipment on the 3R Series Tractors. Cruise control is electronically engaged and disengaged and is located on the right-hand operator console.

| ||||||||||||||

|

LoadMatch power management system

LoadMatch is an industry exclusive and a standard feature on the 3R Series Tractors. If torque requirements increase significantly, the transmission will reduce the tractor's drive speed to compensate for the increased load on the transmission, maximizing torque to drive wheels and minimize stalls. Controls automatically adjust LoadMatch compensation depending on the tractors application. PTO applications require less engine speed fluctuation, therefore adjusts the amount of droop depending on PTO speed. This adjustment increases efficiency and optimizes engine speed and torque output based on tractor application.While typically left on, LoadMatch can be turned off with the right-hand console controls. | ||||||||||||||

|

MotionMatch

Longer accelerate and decelerate distances. | ||||||||||||||

|

SpeedMatch

Rotary tilling or spraying applications are examples of where SpeedMatch can be applied. SpeedMatch will work in both the forward and reverse set speeds. NOTE: Automotive-style cruise control and SpeedMatch can be used in conjunction with LoadMatch to maximize productivity. Sauer-Danfoss is a registered trademark of Sauer-Danfoss, Inc. | ||||||||||||||

PowrReverser™ transmission allows for clutchless direction changesThe PowrReverser transmission, available on 3033R and 3039R Tractors, offers a hydraulically-shifted forward-to-reverse transmission. This allows for clutchless shuttle shifting between forward and reverse with one lever for quick and easy direction change.

The 12x12 PowrReverser transmission's hydraulically-actuated wet clutch takes the place of the dry-type traction clutch. Two multi-disk clutch packs (one forward and one reverse) are hydraulically actuated when the directional (reverser) lever is placed in either the forward or reverse position. | ||||||||||||||

|

Forward/reverse clutches

|